ALL IN STOCK WELDING TABLES & ACCESSORIES SHIP OUT IN JUST 1 TO 3 BUSINESS DAYS

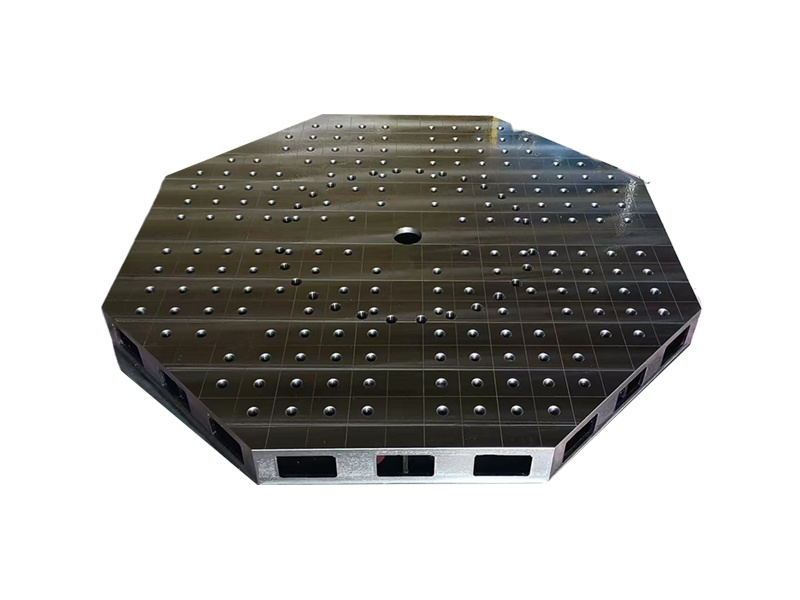

D28 cast iron weliding table

※ All the above-mentioned technical parameters can be customized according to customer requirements ※

WhatsApp: +86-18064087276

Download Files

Tag:

Category:

Product parameters

| D28 product | Specifications |

| 3D welding table | 800x800x200 |

| 1000x800x200 | |

| 1000x1000x200 | |

| 1200x800x200 | |

| 1200x1000x200 | |

| 1200x1200x200 | |

| 1500x1000x200 | |

| 1500x1500x200 | |

| 2000x1000x200 | |

| 2000x1500x200 | |

| 2000x2000x200 | |

| 2400x1200x200 | |

| 3000x1500x200 | |

| 3000x2000x200 | |

| 4000x2000x200 |

The universal D28 3D welding table meets all requirements for horizontal as well as vertical applications. With this modular system, setting up your parts exactly and quickly is a snap: Machine housings, racks, frames, cross members, mounting brackets, railings, stairs, gates, control cabinets, sheet metal coverings and much more.

3D Welding Tables are the ideal solution for applications where precision, repeatability, and efficiency are essential—whether you're performing manual welding or using robotic systems. Designed to eliminate unnecessary rework, these tables help ensure your structures are accurate from the start.

The 25mm thick worktop features a densely ribbed design, reinforced by a rigid substructure, delivering outstanding flatness and stability during use. The robust frame resists deformation, even under frequent or prolonged workloads.

Key Benefits:

Perfect for precision welding tasks in all industries

Suitable for both manual and robotic welding setups

Flat, stable worktop for ergonomic and repeatable operations

Reinforced construction for long-term durability

Excellent balance of quality and affordability

Whether you're fabricating small parts or assembling larger structures, the 3D Welding Table delivers the accuracy, stability, and cost-efficiency your work demands.

Reasons to choose us

Craftsmanship

Rigorous selection of materials

Exquisite quality

Strict quality inspection

Fast delivery

Physical manufacturer

Large-scale self-owned factory buildings

A 21,000-square-meter workshop

Perfect production equipment

38 sets of processing equipment

Payment and Distribution

T/T L/C

★ If your order is not large, we can send it to you via TNT, DHL, UPS or EMS, etc.

★ If your order is large, we would recommend that you use air or sea freight through the freight forwarder you specify. We also have long-term cooperative agents.

7 to 10 working days

7 to 10 working days

7 to 10 working days

7 to 10 working days

7-10 working days

FAQ

What are the transportation methods for equipment? Who will bear the freight and customs duties?

The transportation methods include sea freight, air freight, etc., which can be chosen according to your needs. The freight cost can be negotiated and determined, and it should be clearly stated in the contract. Tariffs are usually borne by the customer, and we can also assist in providing relevant information to help you calculate costs in advance.

Is there a discount for bulk purchasing? What are the payment methods?

Bulk purchases can enjoy discounts, and the specific discount amount depends on the purchase quantity and product. You can contact our sales team (email:[ sales@bestweldingtable.com ]; Phone: [+86-18064087276]) for further discussion. Payment methods support common foreign trade payment methods such as letter of credit and T/T (telegraphic transfer) to ensure transaction security.

How long is the warranty period for the equipment? What after-sales services are available during the warranty period?

The equipment warranty period is 1 year. During the warranty period, we provide free maintenance (non human damage), regular follow-up, technical consultation and other services. If the device malfunctions, you can call the after-sales hotline or provide feedback through our online customer service website. We will respond quickly and arrange professional personnel to solve the problem.

Does the product meet international quality standards? Can you provide certification documents?

Our products are strictly produced in accordance with international advanced standards and meet multiple international quality certifications such as ISO and CE. If you need it, you can download relevant documents from the "Qualification Certification" section of the website at any time, or contact our customer service personnel to obtain them.

How long is the production cycle for customized machine tools? How to ensure timely delivery?

The general production cycle for customized machine tools is 2-3 weeks, depending on the complexity of the customization. We have established an efficient customized service process, with a professional project management team following up and coordinating from requirement communication to installation and debugging. We strictly control the time nodes of each link and arrange production plans reasonably to ensure timely delivery.

Can you customize machine tool equipment according to our needs? What customizations are supported?

tolerable. We have a professional technical team that can customize machine tools from various aspects. Can customize machine tool types that are suitable for different industries, such as automotive manufacturing, aerospace, etc; Customized cooling, cutting tools and other functions for special processing techniques; It can also customize machine tool size specifications according to workshop space layout, and provide automation and intelligent upgrade customization solutions.

Inquire

Note: Please complete this form, and we will contact you by the next business day.